|

|

| ORIGINAL ARTICLE |

|

| Year : 2014 | Volume

: 9

| Issue : 1 | Page : 39-42 |

|

Appraisals for potential hazards in the operational environment and facilities of petroleum refining and distribution industry in Nigeria

TIN Ezejiofor1, HC Nwigwe1, FOU Osuala2, MOE Iwuala2

1 Department of Biotechnology, Federal University of Technology, Owerri, Nigeria

2 Department of Biology, Federal University of Technology, Owerri, Nigeria

| Date of Web Publication | 15-May-2014 |

Correspondence Address:

TIN Ezejiofor

Department of Biotechnology, Federal University of Technology, Owerri

Nigeria

Source of Support: None, Conflict of Interest: None  | Check |

DOI: 10.4103/9783-1230.132558

Objective: To appraise operational environments and facilities of petroleum refining and distribution industry in Nigeria with a view to establishing the potential hazards/health risks Design: A prospective study. Setting: The Operational environments- facilities and activities of PHRC and PPMC, Eleme near Port Harcourt, Nigeria. Materials and Methods: Personal walk-through of the operational sites and facilities using checklist, participation in the various units' activities, and oral interviews of staff concerning the health hazards/risks of their workplace. Results: Five main occupational hazard categories were revealed- physical, chemical, biological, psychosocial, and ergonomic hazards. Sundry job exposures to these workplace hazards are suspected to be responsible for the accidents, injuries morbidities, and mortalities recorded in this industry. Conclusion: Current state of facilities and activities at the operational units of petroleum refining and distribution industry in Nigeria are fraught with several hazards, categorizable into five main hazard types, a situation that disposes staff to sundry health risks. Facility upgrade and industrial health services updates are thus warranted for abatement of hazards/associated health risks, and securing safer facilities and healthier work environment. Keywords: Nigeria, Petroleum refining and distribution industry, Potential Hazards, Risk assessment

How to cite this article:

Ezejiofor T, Nwigwe H C, Osuala F, Iwuala M. Appraisals for potential hazards in the operational environment and facilities of petroleum refining and distribution industry in Nigeria. J Med Investig Pract 2014;9:39-42 |

How to cite this URL:

Ezejiofor T, Nwigwe H C, Osuala F, Iwuala M. Appraisals for potential hazards in the operational environment and facilities of petroleum refining and distribution industry in Nigeria. J Med Investig Pract [serial online] 2014 [cited 2018 Aug 24];9:39-42. Available from: http://www.jomip.org/text.asp?2014/9/1/39/132558 |

| Introduction | |  |

How safe is the work place? This is a question that bothers many occupational toxicologists, industrial hygienists, and others with stake in the field of occupational health and safety. Indeed, the safety of many workplaces can hardly be guaranteed. Thus, in spite of the immense benefits derived from work, work itself has become a source of several deaths, ill-health, and injuries, as are clearly illustrated by data from relevant authorities including the World Health Organization (WHO) and International labor organization (ILO). [1],[2],[3] WHO in the World Health Report for the year 2000 [4] concluded that workplace hazards are responsible globally for 37% of back pain, 16% of hearing loss, 13% of Chronic Obstructive Pulmonary Disease (COPD), 11% of asthma, 10% of injuries, 10% of lung cancer, and 2% of leukemia. The magnitude of the problem is said to be grave for the developing countries. In spite of the difficulty in obtaining information concerning occupational diseases and injuries in developing countries due to lack of comprehensive and harmonious data collecting systems, ILO still estimates that 2 million workers die each year from work-related injury and illness. In 2002, in sub- Saharan Africa alone, ILO estimated more than 257, 000 total work-related fatalities, including about 55,000 injuries.

Thus, in both industrialized and developing countries, the rapid pace of technological changes combined with the persistence of unsafe or environmentally-threatening working conditions have served to focus attention on the need to create a safe, healthy work environment and to promote a safety culture at the workplace. An important starting point for achieving this target is risk assessment, since by this, all aspects of work are considered in a systematic evaluation that not only identifies the hazards of the workplace and the specific groups of workers at risk for purposes of instituting the right kind of preventive/control measures, but also other measures to be taken to comply with the employer's duties under the regulations, which include among others, the assessment of health and safety risks faced by workers in the normal course of their activities or duties and the prevention of occupational risks. [2],[5],[6],[7],[8] Petroleum refining and distribution are among the occupational activities perceived to be hazardous. Once extracted, crude oil is transported to an oil refinery where complex hydrocarbon compounds are separated and converted through various refining operations (fractional distillation, cracking, solvent extractions, then other treatments including formulating and blending) to become useable fuel sources. Present day refineries produce a variety of products including many required as feedstock for the petrochemical industry. The process of refining oil manufactures nearly 2,500 useful products. [9] Petroleum refining and distribution industry in Nigeria, as elsewhere, constitute a giant industry with many complicated systems. The Port Harcourt refinery complex situated at Alessa-Eleme near Port Harcourt consists of two refineries in one: The old Port Harcourt refinery (Area 5) established in 1965 with current production capacity of 60,000 barrels per stream day (bpsd), and the New Port Harcourt Refinery (Areas 1- 4) commissioned in 1989 with installed capacity of 150,000 bpsd. Both refineries have combined installed capacity of 210,000 bpsd. [10]

Given the complexities of this work environment and facilities, and given that workers are behind their operations, it is possible that these workers might be liable to certain health hazards on account of sundry job exposures. It has, therefore, become very imperative to appraise these facilities and their associated operational activities with a view to defining the true nature and extent of real or potential hazards arising from them that might put the workers at certain risks to health or even life ultimately, and this forms the main aim of this study. Most of the studies done with respect to petroleum industry in Nigeria are mostly animal studies centering mainly on the effects of petroleum products on the environment with emphasis on ecological species other than man (mainly terrestrial and aquatic resources). [11],[12],[13],[14],[15],[16],[17] Apart from our earlier attempt to define the hazards of this industry, [18] there had been no previous study with detailed report on work environment and facility appraisals for petroleum refining and distribution activities in Nigeria. Absence of such study is responsible for a dearth of data regarding the comprehensive definition of real and potential hazards of this sector in the Nigerian environment or setting, and this forms the scope of what this study (a furtherance of the previous one) seeks to address.

| Materials and Methods | |  |

The study target was the facilities of and occupational activities of the studied establishments:

- Port Harcourt Refining Company Ltd. (PHRC) (Petroleum refining industry) and

- Pipelines and Petroleum Marketing Company (PPMC) (Petroleum distribution industry). Operations of the establishments under study are carried out in departments, which for the purposes of this study were split further into many smaller units in order to capture the specific hazards of the various facilities and the equally many different functions (activities) performed by different sections of a particular department in their particular locations.

Ethical clearance and permission to study these industries were obtained from the institutional review committee of the supervisory ministry (Petroleum Resources).

The study was conducted through personal walkthroughs, involvement in the operations and activities of the various departments/sections of the establishments, and interviews with a cross section of staff during the study period to obtain first hand information. Secondary data relating to the study of hazards of the industry by the industrial occupational physician was also used. Data emanating from these sources were collated and analyzed.

| Results | |  |

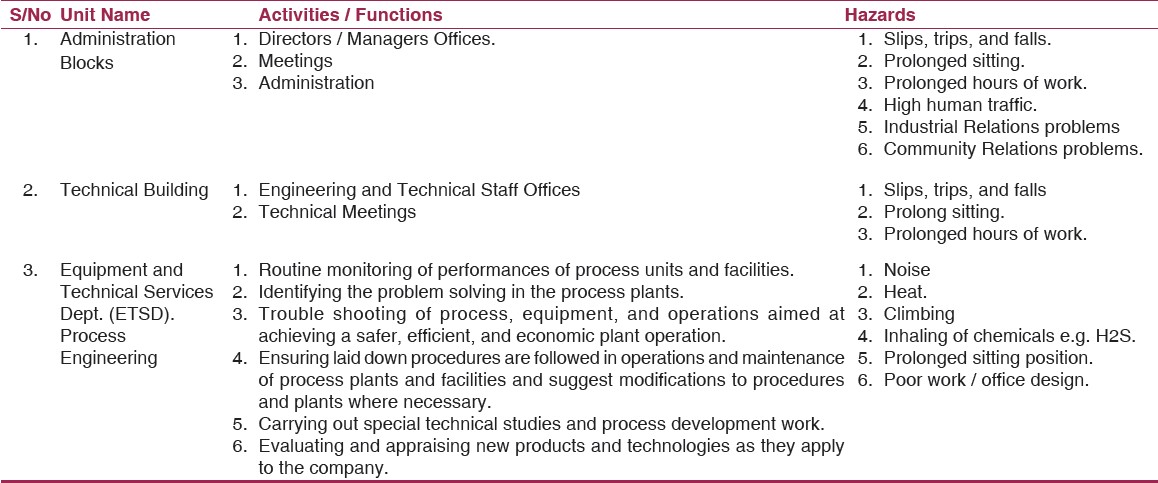

Personal walkthroughs, interactions with staff through oral interviews, and personal involvement in the activities of the various work units during the study period revealed the hazards in the various operational units of this industry. These were collated with available secondary data and presented in [Table 1].

Another important discovery during the personal walk-through is shown in plates 1 and 2. Some operational facilities of the studied establishments were observed to have become obsolete and defective, thus allowing the release of hazardous pollutants into the air environment. | Table 1: PHRC and PPMC: Operational units, activities, and identified hazards

Click here to view |

| Discussion | |  |

Personal walk-through and involvement in the activities/operations of the various departments of the establishments as well as interactions/interviews with staff during the study period offered immense personal insight into the hazards of the various facilities and operational units [Table 1], revealing that oil refining and distribution activities are indeed fraught with several hazards. This observation was corroborated by the views of staff themselves as they catalogued a wide range of hazardous experiences encountered over the years in the course of discharging their work demands. An appraisal of the findings revealed that the identified hazards fell into five major hazard classification categories reported previously by Ezejiofor et al.[18] namely physical hazard, chemical hazard, biological hazard, psycho-social hazard, and ergonomical hazards.

The chemical hazards were many and of diverse nature, essentially coming from the myriad of chemical substances involved either as production/process chemicals (as compiled in the material safety data sheet (MSDS), products, or part of the discharged effluents including solids, liquids, solvents, gases, mists, vapors and fumes (including fuels and welding fumes), oil spills, flammable and/or explosive substances. The biological hazards are mainly from exposure to disease agents of infections and infestations such as bacteria, viruses, fungi, helminthes and protozoan parasites, other pathogens, and sundry other conditions that predisposes to diseases and infirmities including bites from rodents, reptiles, and insects including malaria-causing mosquitoes, as well as contamination of food/water.

Psychosocial hazards originate from overloaded work pressure, prolonged hours of work, shift-work/call duty, high human traffic, community and/or industrial relations problems, interpersonal relations problems and the worries deriving from all these, as well as monotony/boredom obtainable in some sectional operations.

The ergonomical hazards include poor work and office space design, working in confined space, awkward sitting/standing work positions/postures, climbing, manual handling (pushing, pulling, lifting, and carrying) as well as mechanical accidents and other accidents (including road transport accidents) that are very common to most sections of the industry.

This workplace and facility appraisals revealed that the findings are in tandem with those reported previously by Ezejiofor et al., [18] and the established hazards are suspected to be responsible for the several accidents including slips, falls from heights, road/water transport accidents, fires and explosions, and several other industrial accidents, some of which resulted in accident injuries such as sprains, dislocations, fractures, tears, abrasions, blisters, bruises, cuts, punctures, lacerations, contusions, crush injuries, fire/steam burns, blow/red eyes, chemical splashes/burns, scalds, swellings of body parts with pains and internal injuries, insect stings and other animal bites, gas inhalations, electric shocks, assaults, bullet wounds, and other unclassified accident injuries, [19] as well as variable patterns of morbidities and mortalities [20] also reported previously.

However, studies from other lands have shown that the hazardous nature of oil and gas industry is not peculiar to Nigeria. According to these reports, oil workers are continuously exposed to numerous hazards that include exposure to heat, fires, polluted air, noise, radiations and hazardous chemical materials, including asphalt, asbestos, aromatic hydrocarbons, arsenic, hexavalent chromium, nickel, carbon monoxide, coke dust, hydrogen sulfide, lead alkyls, natural gases, petroleum, phenol, and silica, with far reaching consequences. [21],[22],[23] This same set of hazards have been noted previously in other industrial occupational activities particularly with regards to exposure to noise, heat, dust, and hazardous chemical substances. [24],[25],[26],[27]

Unfortunately, some of the effects of these hazards are also borne by residents and environments far beyond the confines of the generating industries. That the effects of these hazards are not confined to the generating industry and its workers is clearly gleaned from the submissions of Runion [28] on two such hazards- thermal and noise pollutions.

Again, it is noteworthy that most building roofs in and around this industrial host communities usually turn brown within just few months after roofing- perhaps, resulting from the gases, sooths, and other particulate air pollutants discharged from the industrial aerial chimneys, gas flare stack, and/or other defective operational facilities. Indeed, these observations were corroborated by the reports of chemical assessment of atmospheric residual aerosol from satellite stations of these studied industrial sites, [29],[30] in which p H, electrical conductivity and varying concentrations of acid rain gases, non-metallic and metallic ions (including some heavy metals), and particulate matter were reported, with higher concentrations of some of these found in stations closer to the industrial sites. Thus, in these and all other instances of industrially-facilitated pollution, not just the workers, but also all else within and beyond the immediate vicinity of the operational locations are put at great risk of resultant environmental pollution.

In conclusion, the current state of facilities as well as activities at the operational units of petroleum oil refining and distribution industry in Nigeria is fraught with several hazards. Thus, there is urgent need for facility upgrade and industrial health policy/services update in order to mitigate these hazards, thereby securing a safer and healthier work environment for the petroleum refining and distribution industry in Nigeria.

| References | |  |

| 1. | World Health Organization (WHO). Global Strategy on Occupational Safety and Health 1995;1-4.

|

| 2. | Baichoo P, Muchiri F. Risk assessment training in Mauritius. Afr Newslett Occup Health Saf 2010;20:28-9.

|

| 3. | Dyjack D, Dyjack AB. Health hazards of the environment. Dialogue 2000;12:3.

|

| 4. | Anonymous. Workplace Hazards evolving as technologies develop. Afr Newslett Occup Health Saf 1999;9:22-3.

|

| 5. | Machida S. Risk assessment at workplaces (editorial). Afr Newslett Occup Health Saf 2010;20:27.

|

| 6. | World Health Organization (WHO). World Health Report 2000. In: Lehtinen S. Consultation on ILO Safe Work Programme. Afr Newslett Occup Health Saf 2000;10:25-7.

|

| 7. | Katula Y. Risk assessment in Uganda. Afr Newslett Occup Health Saf 2010;20:33-4.

|

| 8. | Kadiri SA. Risk assessment and control in workplaces. Afr Newslett Occup Health Saf 2010;20:35-7.

|

| 9. | Gennaro V, Finkelstein MM, Ceppi M, Fontana V, Montanaro F, Perrotta A, et al. Mesothelioma and lung tumours attributable to asbestos among petroleum workers. Am J Ind Med 2000;37:275-82.

|

| 10. | PHRC Brochure. PHRC, Nigeria′ Premier Petroleum Refining Company 2008. p. 20.

|

| 11. | Orisakwe OE, Njan AA, Afonne OJ, Akumka DD, Orish VN, Udemezue OO. Investigation into the nephrotoxicity of Nigeria bonny light crude oil in Albino rats. Int J Environ Res Public Health 2004;1:106-10.

|

| 12. | Orisakwe OE, Akumka DD, Njan AA, Afonne OJ, Okechi OO. Hepatotoxic and haematological effects of Nigrian Bonny light crude oil in male albino rats. Toxicol Environ Chem 2005;87:215-21.

|

| 13. | Igbo NM, Dede EB, Ayalogu OE. Acute toxicity effects of crude petroleum (Bonny light), kerosene, and gasoline in Albino rats. J Appl Sci Environ Mgt 2001;5:73-5.

|

| 14. | Dede EB, Kagbo HD. Investigation of acute toxicological effects of diesels fuel in rats (Rattus rattus). J Appl Sci Environ Mgt 2001;5:83-4.

|

| 15. | Gabriel UU, Allison ME, Alagoa KJ. Effects of crude oil water dispersion on the haemoglobin and haematocrit of the Afican Catfish, Clarias gariepinus. J Appl Sci Environ Mgt 2001;5:9-11.

|

| 16. | Ayalogu OE, Igbo NM, Dede EB. Biochemical changes in the plasma and Liver of Albino Rats exposed to Petroleum samples (gasoline, Kerosene, and Crude Petroleum). J Appl Sci Environ Mgt 2001;5:97-100.

|

| 17. | Uba EC, Onyekonwu MO, Mbeledogu IU. Modeling environmental contamination: Case study of a potentially polluted area in the Niger Delta. J Appl Sci Environ Mgt 2001;5:77-84.

|

| 18. | Ezejiofor TIN, Iwuala MOE, Osuala FOU, Nwigwe HC. Risk assessment: Prevalent Occupational Hazards in Nigerian petroleum oil refining and distribution industry. J Med Invest Pract 2012;8:24-9.

|

| 19. | Ezejiofor TIN. Patterns of accidents and injuries in Nigerian Petroleum Oil Refining and Distribution Industry. Mary Slessor J Med 2010b;10:23-8.

|

| 20. | Ezejiofor TIN. Morbidity and mortality patterns in Nigerian petroleum oil refining and distribution industry. Mary Slessor J Med 2010a;10:8-22.

|

| 21. | Engler R. Oil refinery health and safety hazards: Their causes and the struggle to end them. Philadelphia: Philadelphia Area Project on Occupational Safety and Health; 1975.

|

| 22. | Gennaro V, Ceppi M, Boffetta P, Fontana V, Perrotta A. Pleural mesothelioma and asbestos exposure among Italian Oil refinery workers. Scand J Work Environ Health 1994;20:213-5.

|

| 23. | Epstein PR, Selber J, editors. Oil- A life cycle analysis of its health and environmental impacts. Report of center for Health and the global Environment. Boston, and Massachusetts: Harvard Medical School; 2002. p. 73.

|

| 24. | Ezeonu FC, Ezejiofor TIN. Biochemical indicators of occupational health hazards in Nkalagu Cement Industry workers, Nigeria. Sci Total Environ 1999;228:275-8.

|

| 25. | Ezejiofor TIN. Anicteric Hepatitis: An occupational hazard in cement industry workers. J Med Invest Pract 2001;3:53-7.

|

| 26. | Ezejiofor TIN, Ezeonu FC. Biochemical indicators of occupational health hazards in Enugu coal miners, Nigeria. Int J Environ Health Hum Dev 2002;3:31-5.

|

| 27. | Ezejiofor TIN, Mba IEK. Serum Bicarbonate levels in Cement factory workers: A Predictor for Occupational Lung Disease. J Med Invest Pract 2003;4:15-8.

|

| 28. | Runion HE. Occupational exposures to potentially hazardous agents in the petroleum industry. Occup Med 1988;3:431-44.

[PUBMED] |

| 29. | Onuchukwu AI, Njemanze GN, Egereonu UU, Okolue BN, Morah ON. An analytical assessment of atmospheric residual aerosol from satellite stations. J Chem Soc 1996;21:69.

|

| 30. | Egereonu UU, Onuchukwu AI. Assessment of atmospheric residual aerosol from satellite stations II: Heavy elemental Pollutants. J Chem Soc Nig 2000;25:23-30.

|

[Table 1]

|